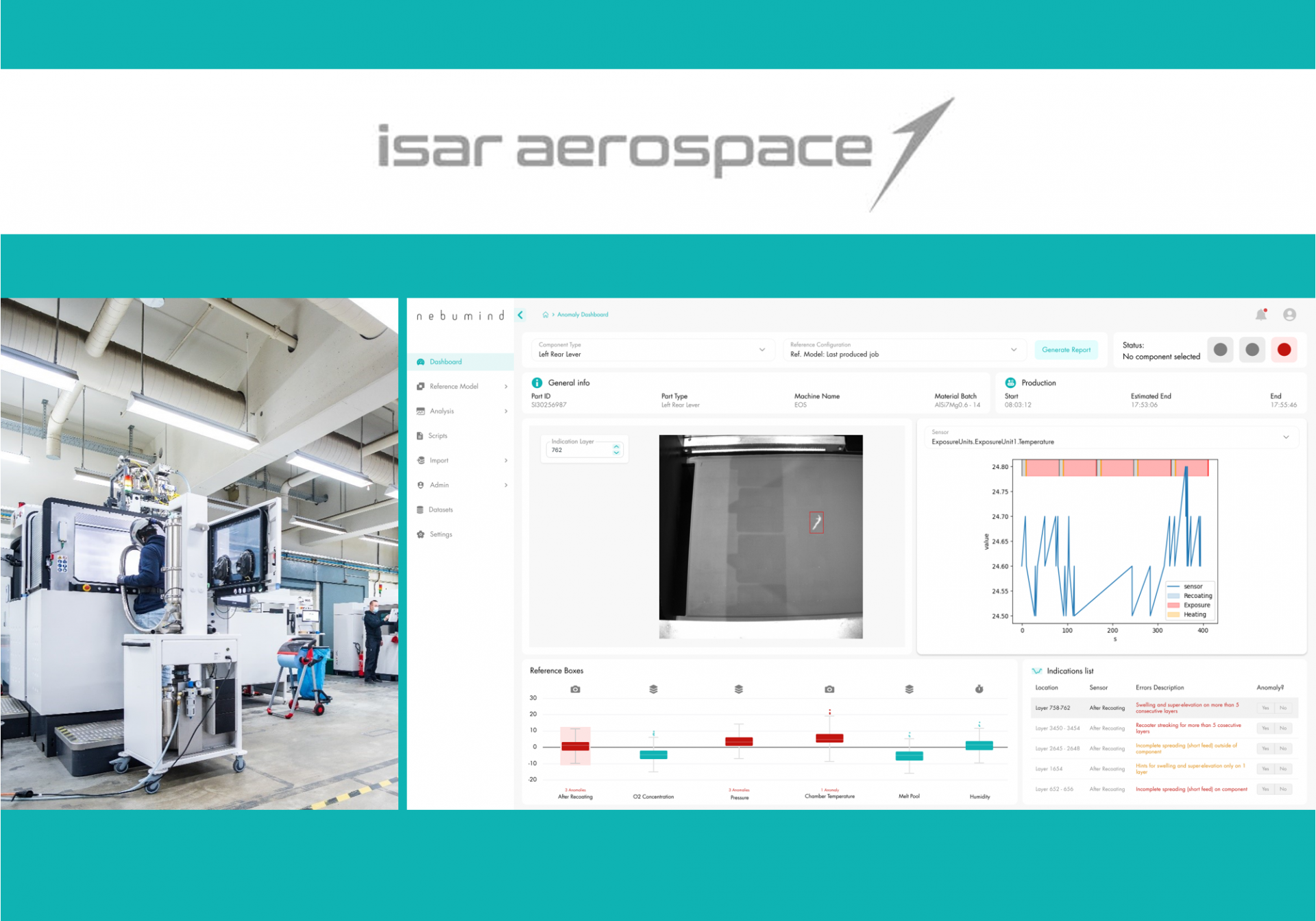

nebumind is thrilled to share the successful integration of the nebumind software into Isar Aerospace engine component production, more precisely into the 3D printing process. The software automates the current manual analysis of recoater images, which means time savings of up to 80% for Isar Aerospace, and moves the “after process” quality control into the printing process in order to report defects at an early stage.