Component-specific data acquisition along the process chain.

The nebumind software merges data from different sources into one generic format and makes it available for manual as well as automated analyses.

The nebumind software collects all machine and sensor data recorded during manufacture of a component – regardless of data format, machine type and process type. This data is stored in a highly structured manner for every single component.

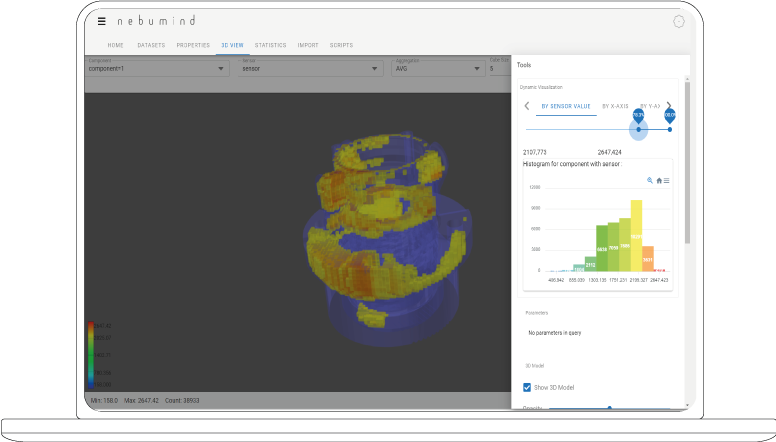

From the data, the software creates digital component twins, which serve not only for intuitive visualization, but also as a basis for calculations and analyses.

nebumind’s analytics applications enable comprehensive quality and process analyses that can be performed manually or automatically.

Manage your data

Organize your data per component, filter for sensors and save your analyses for later

Analyse your component

Detect anomalies and analyse root causes

Compare components & Correlate processes

Compare components side by side and explore correlations across simulation, production and quality data

Monitor your process online

Get alerts in case of deviations, evaluate them and let the software improve its monitoring

Build own analyses scripts

Define own analyses functions and let AI algorithms run

on the data

Create automatic reports & exports

Communicate analyses, customize reports and feed other systems with your results

Data Analytics

data extraction, data structuring, data analysis, customized code development for specific analyses

Automation & Robotics

automation concepts, robotic implementation

and sensor integration (KUKA FSD & RSI)

Manufacturing Digitalization

process digitalization, machine interfaces

Process Expertise

metallic 3D printing, milling, riveting, automated fiber placement, composite winding and braiding

By submitting this form I allow nebumind to store my information and send communications via email. Read more in our data privacy.