When it comes to product quality, the smallest details are enormously important. The nebumind software provides process and quality engineers with exactly the information they need to optimize production and component quality.

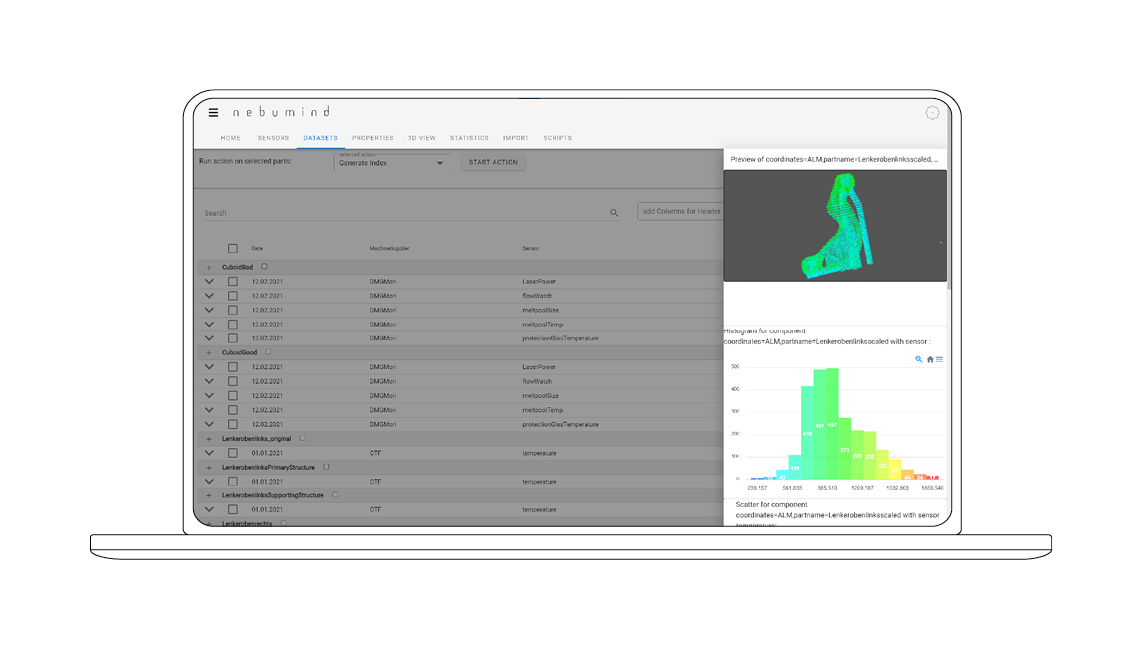

Data of all process steps bundled for each component for maximum transparency

In-process data analytics for early defect detection and constant optimization of threshold values

In-process data analysis for immediately visible effects of process adjustments

Set of tools and algorithms to use machine learning on your spatial data

Even a few micrometers of deviation can turn work pieces into rejects.

The following use cases show how you can avoid such deviations with the right information.

Online Monitoring

at Hufschmied Zerspanungssysteme

Self-learning inline quality control for high-precision milling

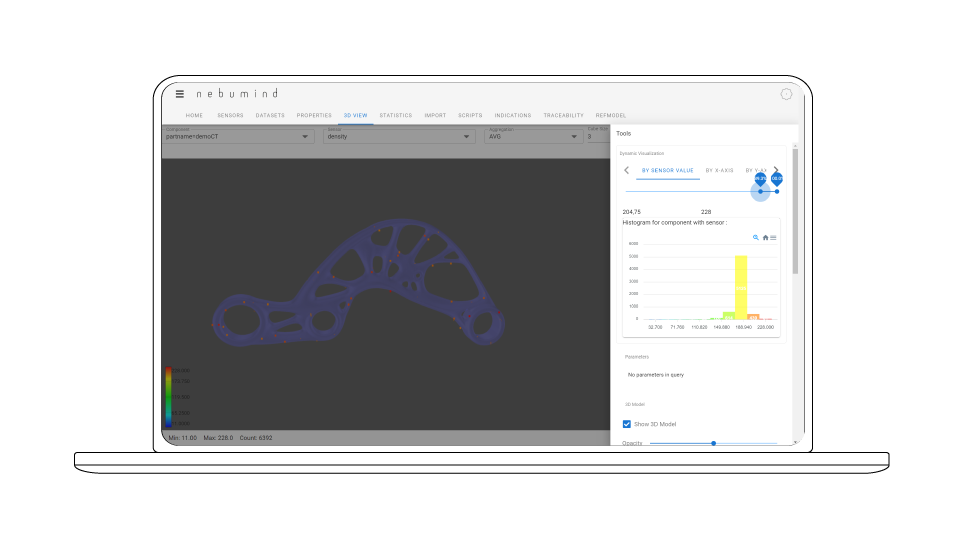

Quality Analyses

at RWTH Aachen University DAP

Powering process understanding and quality control in the AM industry

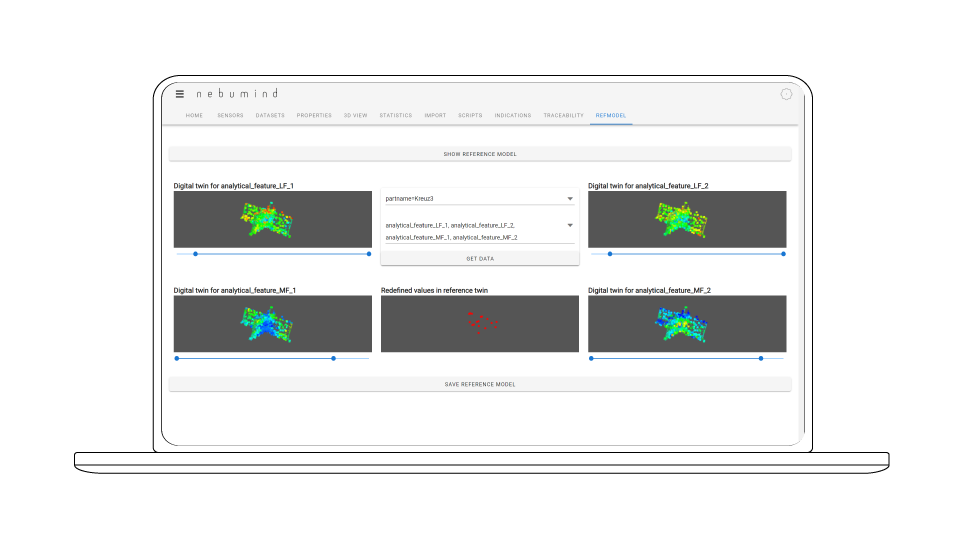

Online Monitoring

at MT Aerospace

Using reference twin to monitor machine changes and their impact