22/10/2020

Using sensor data to improve composite parts and processes – Ginger Gardiner has interviewed our founders, Caroline and Franz, on the origins of nebumind, how the idea emerged, how it can be applied in composite manufacturing and what are their future plans for the company.

The following is an extract, you can read the full article here.

10/21/2020 | 6 MINUTE READ

GINGER GARDINER

Senior Editor, CompositesWorld

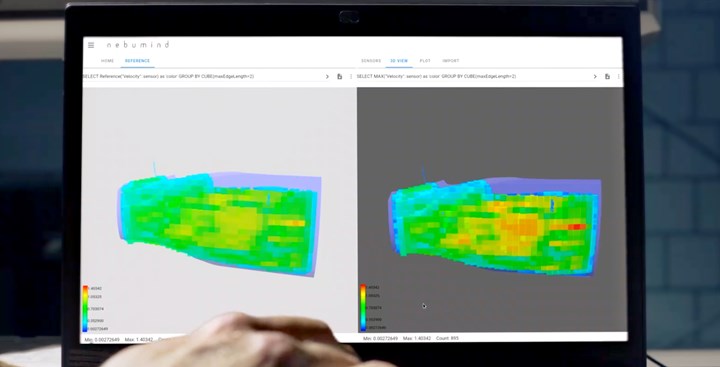

nebumind software builds digital twins from manufacturing data to trace defects, compare manufactured parts, qualify processes, develop tolerance windows for process monitoring and more.

Photo Credit: nebumind

Photo Credit: nebumind

nebumind is a start-up located outside of Munich, Germany. Co-founders Franz Engel and Caroline Albert have spent more than a decade investigating manufacturing processes and part quality for carbon fiber reinforced polymer (CFRP) aerostructures, including jointly managing Airbus subsidiary InFactory Solutions, which developed sensors for AFP inline inspection and resin infusion. “Quality control is a fundamental issue in manufacturing,” says Engel. “I came to see that often the solution is not additional sensors, but being able to quickly and intelligently analyze the data that is already recorded by machines and sensors. Most engineers are not well-versed in data analytics to make use of existing data and, on the other hand, most data scientists have little knowledge of materials and manufacturing processes. The result is that new sensor systems are developed again and again to monitor very specific phenomena, but data is not put together for more holistic analyses. However, if we could compare and aggregate data from different sources, we can increase our manufacturing knowledge dramatically.”

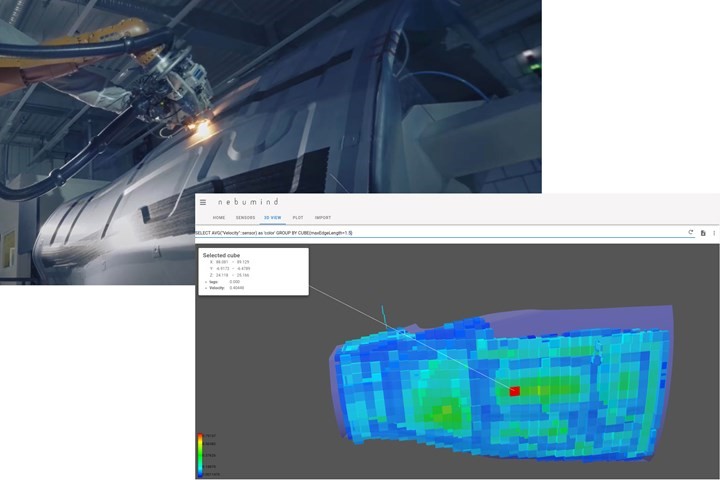

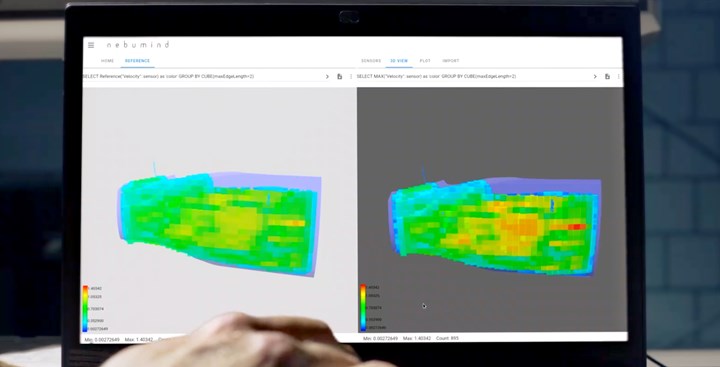

nebumind provides a solution to overcome this barrier via software that allows manufacturing data to be intuitively understood and analyzed in a simple way, by engineers, data analysts and other personnel in the parts production team. “We focus on the quality of produced parts,” says Engel. “Our key finding is that the majority of quality issues always correlate with specific locations within a manufactured part. For example, to identify the root causes of excessive compaction or delamination, it can be important to compare manufactured parts and see how fast the AFP (automated fiber placement) machine deposited fibers at point X, Y, Z in each case as well as the temperature of the heat source and compaction force of the roller at this specific point. Up to now, such analyses had to be done manually, requiring considerable time and effort.”

The new data structuring and visualization that nebumind delivers is a digital twin of the as-produced part.

“Our specialty is to map production data onto every location of the part,” explains Caroline Albert. “There are many software solutions to collect data and put it in a digital twin. Most of these focus on analyses around machine productivity and logistics of entire production lines. They answer business intelligence questions like ‘What is the bottleneck of my production?’ and ‘How efficient is this machine?’ They don’t go as deep into the process of making the composite and analyzing its quality to understand its performance.”

Photo Credit: nebumind

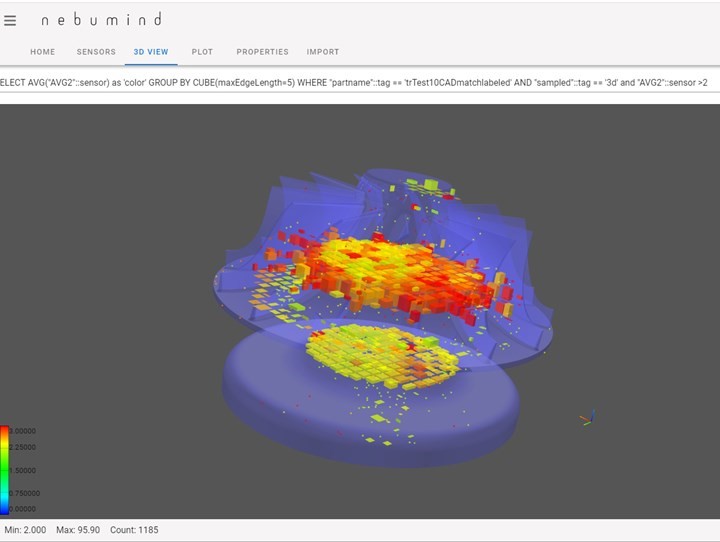

nebumind software can be used to identify locations where the process temperature — in this case, 3D printing — was excessively high. This data can be exported for further analysis and simulation, which enables troubleshooting defects and optimizing the manufacturing process.

“Our focus is on what is happening across the composite part during every process step,” she continues. “Let’s say you produce 10 parts, but every second part has a defect in the top right corner. Our digital twins are composed of the data generated during production of these 10 parts, including temperature, speed, pressure, etc. This data is brought into every part at each location X, Y, Z. Now we can look at all 10 parts and see all the parameters and how they compare to the rest of the part and to other parts. We make it easy and fast to spot outliers, check if they occur always at the same location and identify values that exceed thresholds at certain locations, such as the top right corner.”

“We don’t only collect the data with its time stamp but also with its location stamp — that is, where the machine tooling was at the time the data was recorded,” she explains. “We then combine this data to produce a color-indicated 3D image of the real part. You then collate data from all the parts and analyze outliers and trends. The goal is to improve part quality, reduce scrap and increase manufacturing speed. So, it is possible to trace back quality defects, but you can also analyze how process changes affect part quality, allowing you to fine-tune the process and the machine much faster.”

In the video above, nebumind software is shown working in an AFP machine at Fraunhofer IGCV (Institute for Casting, Composite and Processing Technology in Augsburg, Germany). The software helps to identify locations in the manufactured parts where the temperature exceeded the threshold limits. It also helps to analyze if these are a problem at a specific location. In the future, such insights will be used to generate reference models based on good quality parts that will then be used for online process monitoring.

nebumind’s software is a generic tool that can be applied to various manufacturing processes across the production chain, which means it can also identify correlations between different production steps. Currently, nebumind is being developed for composite manufacturing, 3D printing, milling and gluing. Examples of how the software is being developed and applied are described in the following case histories:

Process troubleshooting. nebumind has worked with Ariane Group (Munich, Germany) to identify part quality drivers in a highly complex 3D printing process. “By identifying anomalies faster in our software, Ariane is able to optimize their process parameters continuously,” Albert explains.

Faster process qualification. MT Aerospace (Augsburg, Germany) wanted to introduce a new robotic process that would normally require time-consuming manual iterations and tests to optimize machine settings. “They used our software to be faster in introducing this new process,” says Albert. “During manufacture, they could see what was happening with the part for each set of machine parameters. If the part had a defect, then it was easier to determine what quality driver was responsible.”

“The key is to develop a reference model for the part production,” Albert explains. “Then, if you change something, you can show that key parameters remain the same and avoid an expensive requalification. Similarly, you can bring additional machines into production more quickly because you have a more precise image of what each machine is producing versus the reference model and how to fine-tune its parameters.”

Enhancing nondestructive inspection (NDI). nebumind’s software also has the ability to make nondestructive inspection (NDI) more powerful. For example, computed tomography (CT) is used increasingly to provide very detailed analysis of composites including porosity, fiber orientation and fiber volume. “As done with Otto Fuchs for a metal 3D printed part, we can now correlate CT to process data, by location, in the part,” says Engel. “We found very interesting correlations that we currently analyze in more detail with Otto Fuchs.”

The nebumind software is available by license, and continuously updated. For now, the company is focused on high-quality parts in aerospace, though it may look at automotive and other markets in the future. In February 2020, it announced its partnership with Fraunhofer IGCV to develop artificial intelligence solutions based on nebumind software to optimize production processes for CFRP aerostructures. “We have also set up a permanent edge computer here that can be used for customer projects to record digital component twins for AFP,” says Engel. The DLR Center for Lightweight Production Technology (ZLP, Augsburg, Germany) next door to the IGCV is also in discussion to integrate the nebumind software into their digital manufacturing system.

Photo Credit: nebumind

nebumind software can be used to create reference models from good quality parts. The reference model is then used to monitor newly manufactured parts live and to analyze differences vs. the reference model for parts and process optimization.

“We are in discussions with three AFP system suppliers to integrate our software as a standard tool in their machines,” notes Engel. “We are also targeting other process steps in the CFRP production chain because we want to integrate that data into a cross-process overview of the digital twin to find correlations between different production steps and also final quality control. To overlay data for every step in the part process chain is a very powerful method for understanding both the part and process performance.”

The software is now being used in a variety of pilot projects and nebumind is looking for further projects with different processes. “We believe this is a very versatile and powerful tool for improving composite products and processes,” says Albert, “but we have only just started exploring what is possible.”

Caroline Albert