06/11/2020

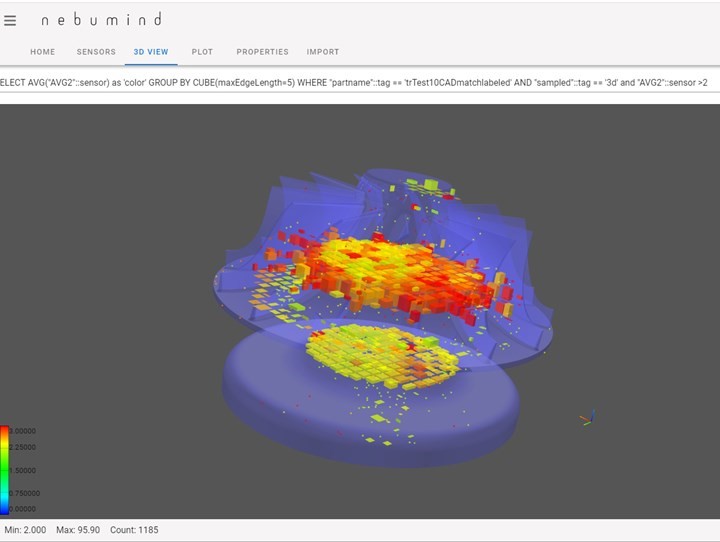

We want to share with you our new video, demonstrating our software in a polymer 3D printing process. While other monitoring solutions only tell you IF there is a quality defect, our software also tells you WHERE it is.

This way, it helps the operator locate threshold violations, analyse their impact on part quality and consequently reduce unnecessary waste – no matter whether applied during commercial 3D printing or the manufacture of space components.

This new feature is also the start for implementing local instead of global threshold levels for manufactured parts – allowing for temperature differences in the upper right corner and lower left corner of a part, for example. The implementation of local thresholds has the potential to reduce unnecessary waste, i.e. good quality parts wrongly declared as waste, by up to 90%.

Caroline Albert