During the pre-development and qualification of a manufacturing process for Ariane 6 serial production, MT Aerospace AG uses the nebumind software to gain a faster understanding of process-relevant influencing factors and to significantly reduce the number of test series required for qualification. The preparation and visualization of the production data in the nebumind software offers MT Aerospace the opportunity to gain new insights into influencing factors and correlations more quickly, to abort failed tests earlier and to optimize the correct process parameters more quickly. The introduction of the new process was shortened by at least 6 months.

–

Dr. Georg Heinrich, Head of Production Development, MT Aerospace AG

„Thanks to the nebumind software, our learning curve during the introduction of the new production process was significantly steep. Development, qualification and introduction were considerably shortened. We therefore want to continue using nebumind software in the future to simplify process optimization and make our development and production much more agile.“

As a subsidiary of the space and technology group OHB SE, MT Aerospace develops and produces key components for the European launch vehicle Ariane 6, including components for the tanks. Metal sheets are formed into the desired shape in a complex, highly automated forming process.

The complex forming process was adapted for the serial production of the Ariane 6. The pre-development and qualification of a new manufacturing process in the aerospace industry is extremely complex – both in terms of time and resources. The manufacturing process is evaluated in a test phase: Trials are carried out, the results are analyzed, settings are changed and correlations between several influencing factors are investigated. Data is already collected in this phase, processed in Excel tables and analyzed with specially programmed macros. However, these macros reach their limits with increasing amounts of data and later lead to a high level of effort in maintaining the tool.

MT Aerospace was also faced with this challenge when introducing the new forming process and expected this manual approach to take several years to implement – time that would have tied up capacity and would not have been able to keep up with the tight schedule for Ariane 6.

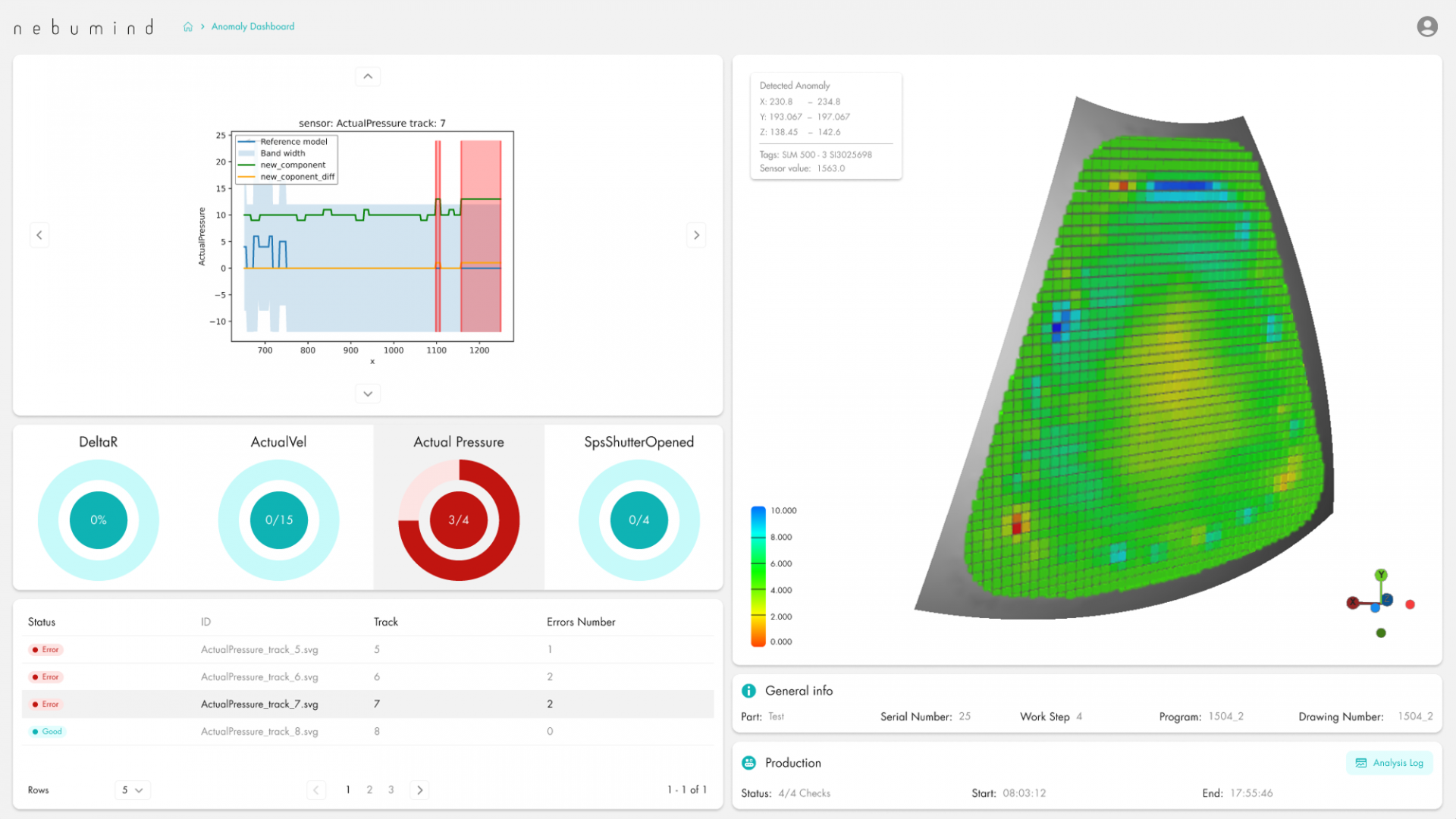

With the promise of providing faster insights through the processing and visualization of production data, nebumind supported both the pre-development and the qualification of the new production system. nebumind already provided support by connecting robots and sensors and by automating data collection. During the first test runs of the new forming system, production data such as the machine speed, the kinetic energy applied and the resulting geometry or forming were recorded or calculated and visualized in the nebumind software as a „digital twin“ of the manufactured component. This allowed the kinetic energy introduced and the resulting deformation to be correlated and an automated way of optimizing the process parameters to be found.

After pre-development, the nebumind software also played a central role in the qualification of the process in order to analyze the stability of the process and verify whether the parameters were being adhered to. The parameters will also be continuously monitored with the nebumind software in the future to keep the process stable.

The automated data acquisition, preparation and structured provision is an ideal basis for machine learning, which will continuously optimize the process in the next step.