08/10/2021

Nowadays the efficiency potential in milling has shifted from the actual milling process to the quality assurance afterwards. Together with our partner Hufschmied Zerspanungssysteme, we transform the previously purely visual quality control of a worker into an automated quality control which is self-learning with every new milling job.

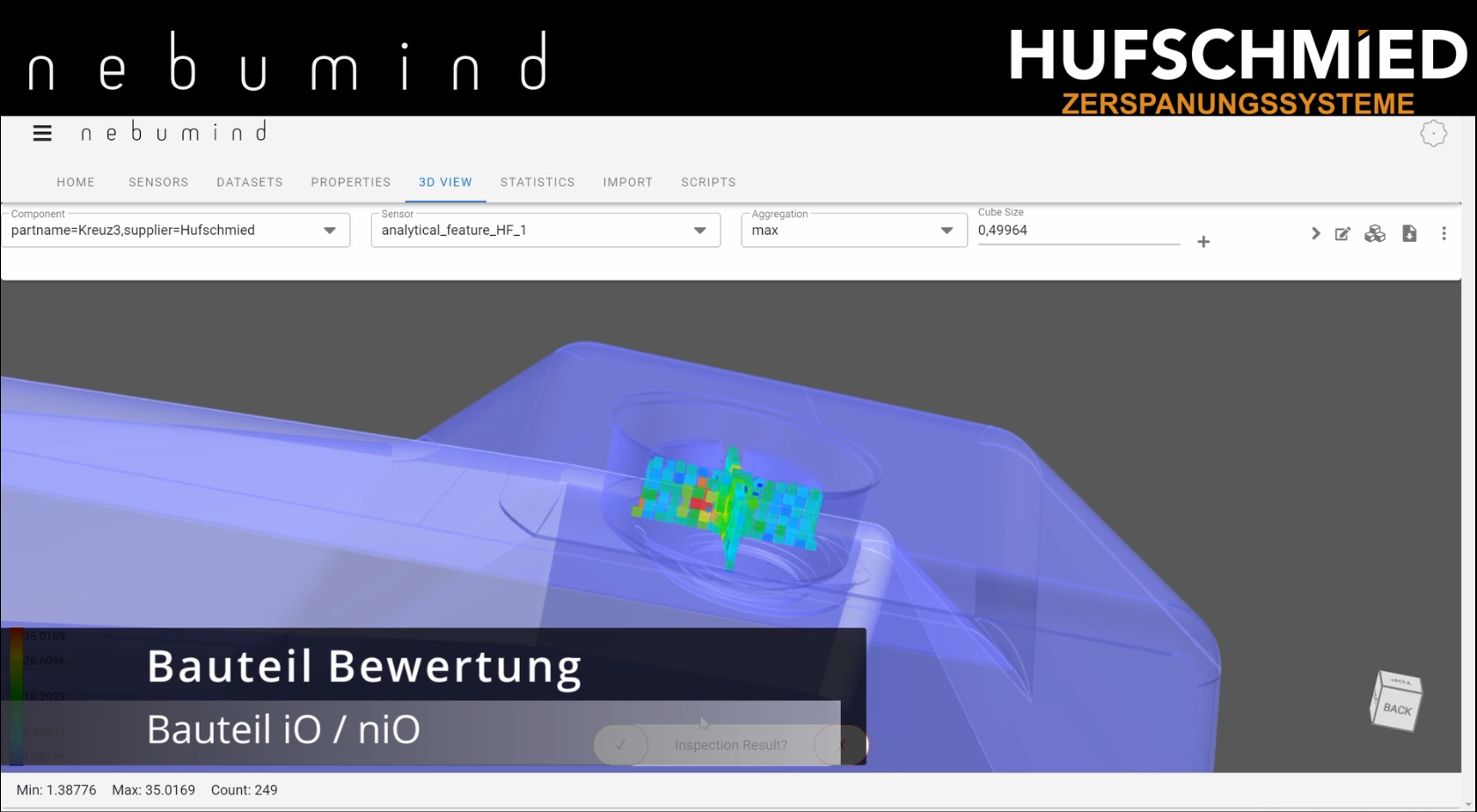

Hufschmied has brought its novel Sonic Shark technology to the market, a sensor system measuring the vibration on the workpiece during the milling process. The Sonic Shark system is now extended with the nebumind software mapping the vibration data onto the component, creating a „digital component twin“.

Anomalies in the vibration data can be located and evaluated by a worker. The valuation is fed back into the nebumind software to self-learn and optimize its anomaly detection. This self-learning defect detection gives manufacturers new potential to save time and costs in quality assurance.

We are excited about our partnership with Hufschmied and are looking forward to more joined project in the field of metal cutting.

Hufschmied Zerspanungssysteme GmbH has more than 25 years of experience in the development and production of process-optimizing, material-related tools and is one of the leading manufacturers of cutting tools in the field of new materials in Europe.

Caroline Albert