03/03/2021

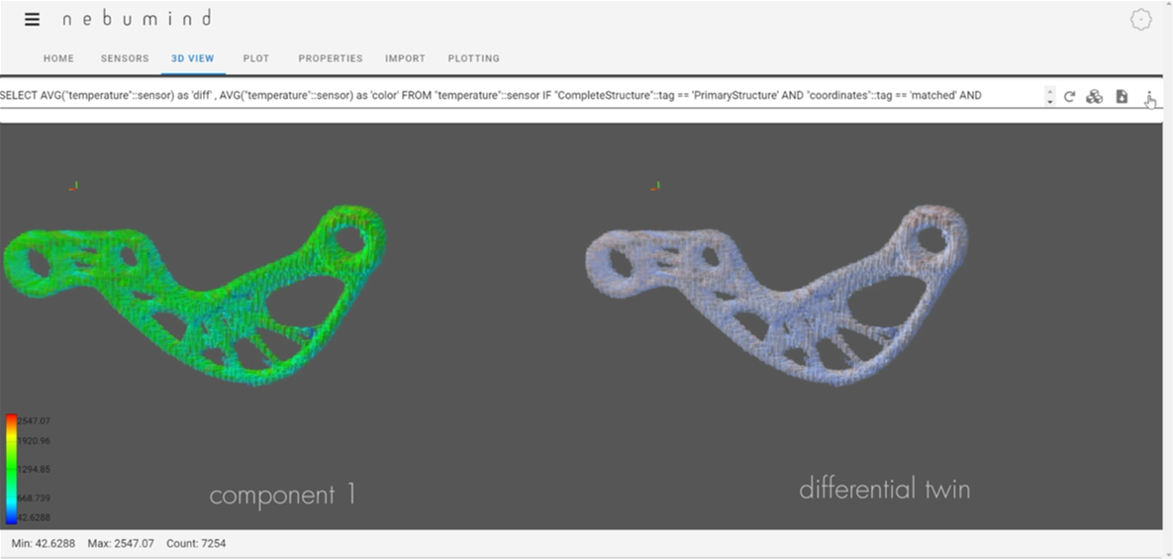

We want to share with you our new video, demonstrating our software in metal 3D printing to analyse the quality of multiple components simultaneously. It helps monitor process stability by evaluating process deviations, detecting defect patterns, and predicting machine maintenance.

Process stability is key in manufacturing to keep cost of non-quality at a minimum. With the nebumind software, manufacturers can compare multiple components simultaneously, evaluate process deviations and detect defect patterns.

This has one significant advantage over other predictive maintenance concepts: Maintenance needs are not decided based on machine anomalies, but based on the quality drift of manufactured components – applying predictive maintenance even more effective.

Caroline Albert