02/10/2020

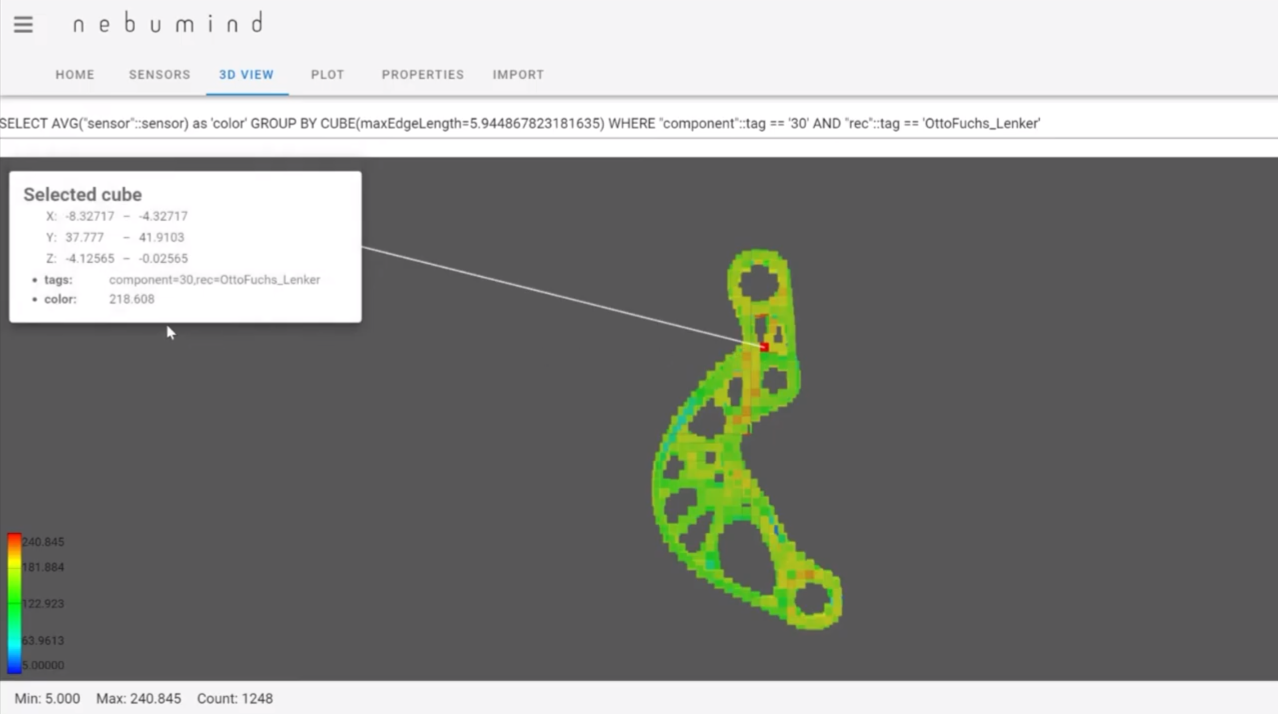

We are excited to give you a first glimpse of our software. Based on the example of a metal part 3D printed by OTTO FUCHS, we demonstrate how our software collects and visualizes manufacturing data to enable fast and simple quality analyses. Whether you want to trace back quality defects, monitor the quality of your part online or simply document your manufacturing quality – your analysis options are endless.

The advantages of our software over existing analytics tools are as follows:

Caroline Albert